WHAT ARE THEY?

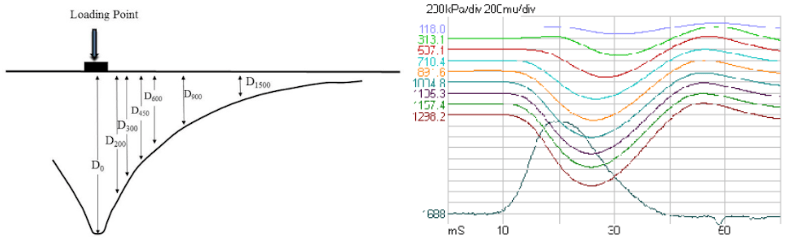

Falling Weight Deflectometers (FWD) operate by measuring and applying an impulse load to a surface. This impulse load causes a vertical deflection in the surface. The vertical deflections are measured at various distances along the load plate axis using geophones to record data. During the testing, surface temperature, air temperature, Stress, Force, and Deflections are recorded. With an integrated GPS, the coordinates and path of surveying are recorded.

Dynatest Model 8002 trailer-mounted system is an example of a Falling Weight Deflectometer. This model is equipped with 8 geophone sensors with 14 total housing positions along the x and y axis with respect to the load cell. This system has a load that ranges from 5,000-29,000 pounds force. A built-in Distance Measuring Instrument on the wheels of the trailer records the distance between stations and the total survey distance.

DELIVERABLES

Testing is carried out according to ASTM D4694 and D4695, where tests are carried out at a specified interval or at target locations (e.g. Joints in PCC Pavement). The deflections of these tests can be used to determine:

1. Back calculation of pavement layer moduli

2. Subgrade resilient modulus

3. Load transfer efficiency (LTE) across concrete joints

4. Overall stiffness of pavement

5. Effective Structural Number (SNeff)

6. Remaining life

7. Required overlay thickness

8. QA of newly constructed pavements

CLICK TO LEARN MORE ABOUT FWD (FALLING WEIGHT DEFLECTOMETER) TESTING